Warehouse Management

Manufacturing warehouse management made easy.

Realize the true power of streamlined warehouse processes and unlock their potential for your business

Optimizing your raw material and finished goods warehouses can have an enormous impact on your business. From labor optimization to reductions in inventory shrink, empower your team with the tools they need to get the job done better, faster, and more accurately. It is time to realize the true power of streamlined warehouse processes.

Experience New Levels of Warehouse Efficiency.

Directed Put-Away.

Streamline your warehouse while increasing inventory accuracy and reducing inventory shrink. Whether it’s raw materials or finished goods, Cella Directed Put-Away will maximize your space utilization and drive efficiency throughout your manufacturing operations. Our rules-based engine monitors compliance and tells your team exactly where inventory needs to go.

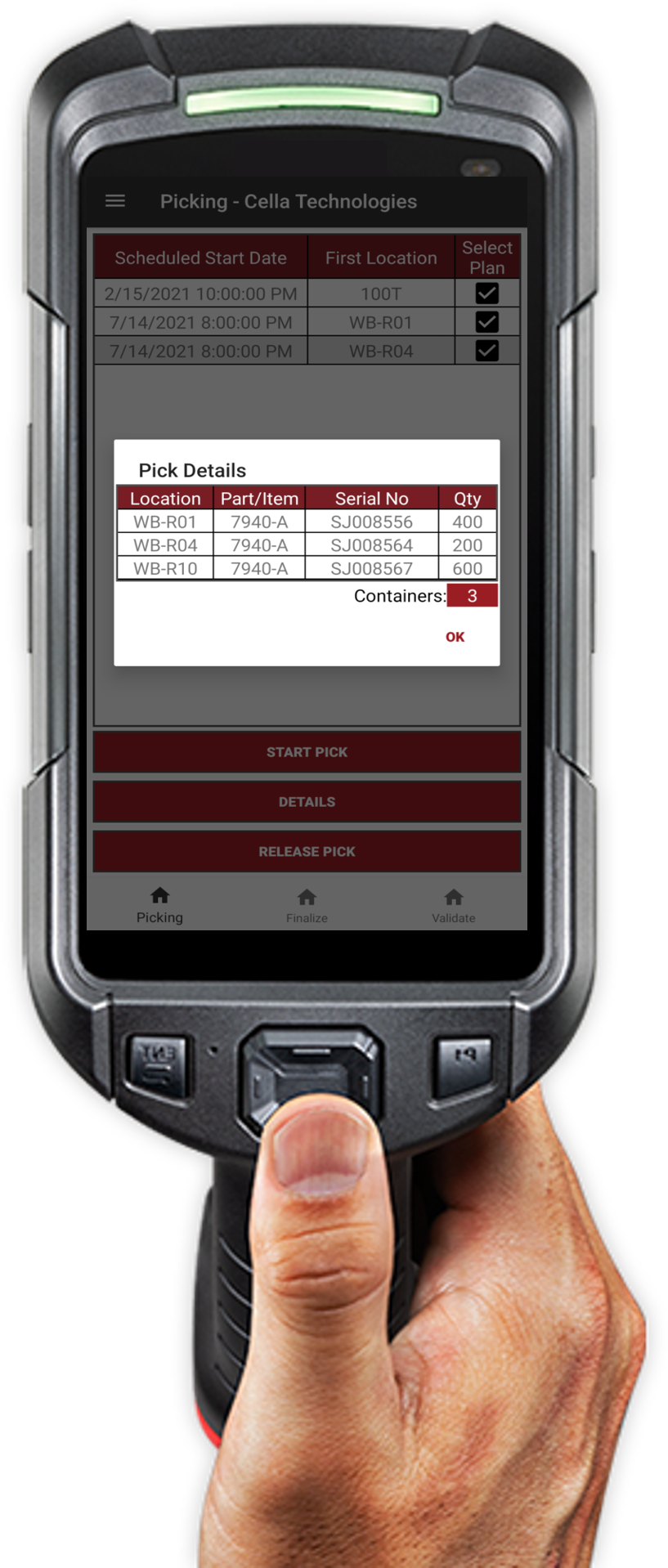

Directed Picking.

Spend less time wandering the aisles of your warehouse and spend more time delivering value to your customers. Eliminate hours of wasted time searching for inventory and increase labor efficiency with a directed picking tool that understands your business and is driven to optimize your labor.

Kitting.

Streamline your shop floor operations and optimize space with the Cella Kitting tool. Build master units in the warehouse, tailored to your specific manufacturing operations. By consolidating components into configurable kits, you can free up valuable lineside space and unlock incredible efficiency for your warehouse team.

Warehouse Management | Efficiency At Work

”Our cultures are similar – small agile teams that get things done, so it was a natural fit. The value the WMS and the support the Cella team provides for the available budget was significantly greater than other WMS options we considered.

Greg BeshoreBeta Technologies

Warehouse Management | FAQs

Is this another Inventory management system I will need to manage?

No, we integrate directly into your ERP, that is the one source of the truth for your business data and we want to keep it that.

What are some of the available business rules for put-away & picking?

Part specific locations/zones, Customer order grouping, Customer shipment grouping, Manufacture date mixing, and many more available based on your business processes.

Are these solutions available individually or just as a suite?

Can your solution accommodate multiple warehouse locations?

Yes, our solution is designed to handle multi-location warehouse operations. Whether you have a single warehouse or multiple warehouse locations, our system can be configured to support your specific setup.

Can your solution handle complex inventory management needs such as serialized or batch-tracked items?

Yes, our solution is equipped to handle complex inventory management requirements, including serialized or batch-tracked items. Whether you deal with unique serial numbers or batches that need to be tracked throughout the supply chain, our system provides the necessary functionality to manage and trace these items effectively.

We exist simply to solve your problems.

© 2025 Cella Technologies. All Rights Reserved.